Water Recycling Unit

WATER AND WATER CONCUMPTION BECOMES WORLDWIDE ISSUE

Van Dijke’s long experience in the washing of produce like potatoes, carrots and other root vegetables, moved Van Dijke to develop a system for additional water treatment. Sedimentable solids, like sand/clay, will be separated from the water without using any chemicals!

The used washwater (mud discharge from the washing line) is pumped to a water-filtration screen. This screen separates the organic particles, like vines, leaves, bigger sand particles etc. from the water. The water flows from this filtration screen into the sedimentation compartment, meanwhile the organic particles will be removed by the filtration screen belt.

The system is based on the natural aspect of difference in specific weight between the wash water and the sedimentable material (like sand/clay).

The settled soil will be removed from the unit by use of a shaftless auger system. This maintenance free system offers a 100% biological solution for separating soil from water and the water can be reused in your washing line.

With this water recycling unit, in combination with the water filtration screen, the water can be reused in your washing line and reduces the water consumption to an absolute minimum.

HOW DOES IT WORK?

The Van Dijke water recycling units are the perfect solution to create a (closed) recycling system for the easy handling of your sludge/mud, wash water and organic material, without using any chemical additives! This unit ensures you a hassle free control of your water and sludge discharge system.

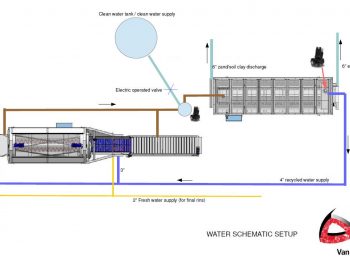

The Van Dijke Water Recycling systems will offer you a perfect solution where no ponds are available or locations where water is hard to get. The system is built up from a main unit (Tare separator) for separating soil/water, a water filtration screen (for removing organical particles) and a sludge discharge system with dirt/sludge loops.

By using these units, you can save up to 95 % water in the line. The use of fresh water in a washing line with a capacity of 40 t/hrs. is about 2 – 4 m³.

The recycled water can be stored in a separate tank and sent from there back into the washing line or to an outside channel.

Van Dijke Group water recycling units will offer you a perfect solution. A combination of water filtration, a separator tank and a sludge discharge system.

COMPLETE TURNKEY WASHING LINES

This machine fits perfectly in a complete Van Dijke washing line with washers, destoners, leaf removers, felt dryers, filtration screens, water recycling system and dirt handling systems. Contact Van Dijke to learn more about the possibilities!

KEY FEATURES:

- GALVANISED (HOT DIP) CONSTRUCTION

- 100% ECO SYSTEM, NO (CHEMICAL) ADDITIVES NEEDED

- SMART DESIGN, EASY MAINTENANCE

- SELF CONTAINED SYSTEM

- OPTION FOR INTEGRATED WATER FILTRATION SCREEN

- SEVERAL SIZES / CAPACITIES AVAILABLE

English

English Nederlands

Nederlands Deutsch

Deutsch